Department of Chemical and Materials Engineering

Labs and Equipment

Gasification

Figure 1. Sawdust Sawdust or wood dust is a by-product or waste product of woodworking operations such as sawing, milling, planning, routing, drilling and sanding. The use of sawdust offer the best technical, economic and environmental alternative. |

Fig 2. Refuse-derived fuel (RDF) Refuse-derived fuel (RDF) is a fuel produced from various types of wastes such as municipal solid wastes (MSW), industrial wastes or commercial wastes. MSW includes combustible and non-combustible wastes that come from household, municipal, commercial, and industrial sites. |

Figure 3. Plastic waste RDF is a value added material with a higher calorific value and a homogeneous particle size. Gasification in fluidised bed is shown as an interesting alternative to plastic waste exploitation. The gasification which have been studied using different feedstock as coal or biomass, can be also used with plastic waste to generate gas with high hydrogen content or synthesis gas. |

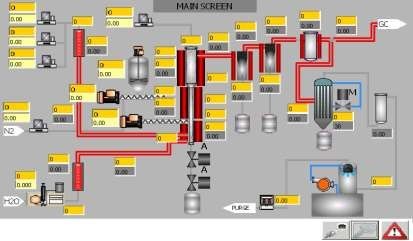

To operate the desired FIC control loop, touch its MFC icon on the main process screen and gas, liquid & react screen will open. This screen will also contain the Set Point and Process Variable boxes, along with a text showing the name of the control loop. The default names are FIC 01 to FIC 05. |

Click on the SIC02 text box on the middle left side of the main screen. Open the Process@ software. Set the frequency on SIC01 to 45Hz and the frequency on SIC03 to 50Hz. SIC03 must be in AUTO mode (MD). To change it to automatic mode, click on the green “M” icon under the SIC04 text box. The icon should change to a red “A” |

Last modified: Mon Aug 07 18:04:24 SAST 2023